Neodymium magnets are the world’s strongest permanent magnets—in theory, they can lift 1300x more than their own weight. They are used in modern electric motors, radars, satellites, loudspeakers, or in sorting bulk material. We use them primarily for quick and comfortable material handling or for clamping workpieces in warehouses and productions with ferromagnetic material.

What is a neodymium magnet?

Neodymium magnets are made by melting neodymium (white soft metal), iron, boron and other elements (dysprosium or praseodymium). In the 80s, neodymium magnets replaced the king of magnets of that time—the samarium-cobalt magnet—and they have earned their reputation as the strongest permanent magnets available in the world, with a wide spectrum of utilization.

In theory, a neodymium magnet can lift up to 1300x its weight. However, this is just a theory. Outer conditions in real life are never optimal for theory to work (surface of the lifted object is rarely absolutely clean, neither is the temperature ideal nor the air pressure optimal). Moreover, neodymium magnets (and lifting magnets in general) are never used individually. They are integrated in a lifting magnet and such integration further decreases their strength. Finally, there is a legal requirement for all lifting magnets to always have a sufficient performance reserve—a lifting magnet should actually be at least 3x stronger than its maximal lifting capacity stated by its producer.

Practical example: In Walmag, we use neodymium magnets to manufacture load-lifting magnets designed for material handling. These magnets (Neo, Neo Hot and Neo EP) have approx. 25-50x higher load capacity than their own weight. For example, our smallest model NEOL 150, weighs only 3 kg and can officially lift loads up to 150 kg.

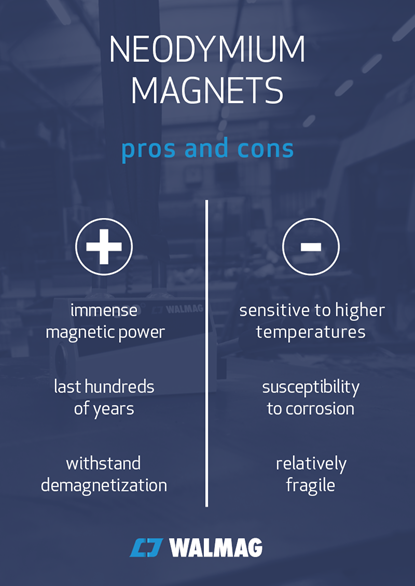

Benefits of neodymium magnets

The biggest benefit of neodymium magnets has already been described—it’s their immense magnetic power. They offer the best price-performance ratio and are basically unbeatable in this aspect.

Neodymium magnets are also relatively resistant and last hundreds of years if maintained well. We can state with 100% certainty that their longevity is greater than the longevity of the main magnet itself (which they are a part of), be it a lifting magnet or a magnetic clamp. They belong among mechanically more resistant magnets (but be careful, they are still fragile) and they withstand demagnetization well.

Cons of neodymium magnets

Neodymium is sensitive to higher temperatures; the raw material loses its magnetic power even at temperatures over 80 °C. Nevertheless, we are able to incorporate neodymium magnet into the construction of the main lifting magnet or a magnetic clamp and thus protect the neodymium magnet so that it can withstand even higher temperatures. For example, our Neo Hot can handle temperatures up to 180°C without losing its magnetic power.

Another flaw of neodymium magnets is their lower resistance against wetness, in particular their susceptibility to corrosion. We can work against this flaw, too, by coating neodymium magnets with zinc, chromium, copper, or with epoxy resin (coating is becoming a standard in the industry). In Walmag, we even use neodymium magnets for clamping material during metal machining or milling work where water is used for cooling. Thanks to their waterproof construction, the magnets inside the working desk stay unaffected.

Neodymium magnets are relatively fragile—a feature common to all magnets. Neodymium are slightly more resistant in comparison with other magnets; however, they still need to be handled with caution.

Practical use of neodymium magnets

Nowadays, neodymium magnets are used in manufacturing an incredible variety of products in the electrotechnical industry, in furniture making, infrastructure, or in notions. We use them to produce load lifting magnets that are used for:

- lifting and handling heavy loads in the warehouse or during production

- clamping workpieces during milling work or other types of metal machining.

A load lifting magnet can be attached to a crane’s hook, which can then easily and swiftly handle heavy loads in the warehouse, stack high columns of metal profiles up to the ceiling, etc. In comparison with attaching heavy loads mechanically, handling by lifting magnets is faster, safer, and more comfortable.

When used in magnetic clamps, neodymium magnets are installed inside a working desk that firmly attaches the workpiece and makes it freely accessible from five sides. Positioning the machined workpiece is much quicker than when using other holding devices, i.e. manual clamps, workers only need a short training to be able to operate the magnetic clamp and, unlike manual clamps, there’s no risk of deforming the machined item.

Load lifting and holding magnets with neodymium are a much better alternative to manual clamping and heavy load handling in warehouses and factories with ferromagnetic material. In case you would like to know more about them or you would like to borrow a magnet for a trial (free of charge), let us know.