WALMAG MAGNETICS s.r.o.

Lifting magnets

Make it easier to handle parts in warehouses, workshops, metallurgy and steel plants. Our lifting magnets can quickly and effectively clamp and release metal materials - you save time and human strength.

More about lifting magnets

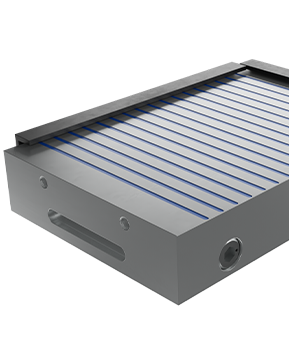

Magnetic chucks

Achieve maximum efficiency in milling, grinding and turning parts. Magnetic chucks immediately fix workpiece. Moreover, there is no mechanical deformation.

Look at magnetic chucks

Demagnetization

Ferromagnetic materials containing alloys hold quite a lot of magnetism after they have been exposed to a magnetic field. To remove residual magnetism, the workpiece must be subjected to an alternating magnetic field which gradually decreases to zero.

I need to demagnetize

Magnetic chucks for milling

Reduce milling downtime with the strongest magnetic chucks by Walmag. Make use of 5-side machining, low vibrations and no workpiece deformation at a press of a buton with electro-permanent chuck Mastermill. Or have your robot load zero-point Neomill Compact permanent magnetic pallets into your automated machining cells.

Show me more about milling magnets

Service

We provide professional warranty and post-warranty service, repair, repair of all technologies, and operator training for all Walmag magnetic applications.

More informations about service

Why Walmag?

CZECH PRODUCTS

LIFTING MAGNETS SOLD

MAGNETIC CHUCKS SOLD

COUNTRIES WHERE OUR MAGNETS ARE USED

WE FOCUS ON SAFETY

PROFESSIONAL SERVICE

Who we are?

Walmag has a long history with manufacturing magnets for the engineering industry. Its roots in Czech manufacturing go back to the 1960s. For 20 years, starting in 1991, it was a part of the international holding Walker Magnetics Group (USA) and bore the name Walker Pilana Magnetics. It became independent in 2011 and changed its name to Walmag Magnetics. Our products are well known and used all around the world.

Blog

Notice of Company Holiday

Dear customers and business partners,We would like to inform you that our company, WALMAG MAGNETICS, will be closed for a company-wide vacation from July 28, 2025, to August 10, 2025. ...Read more

Magnetic Legacy: The History of Walmag Dates Back to the 1960s

Manufacturing magnetic chucks and lifting magnets since the 1960s, Walmag offers global magnetic solutions as an independent brand since 2011. ...Read more

New Magnetic Chuck for SCHOTT Production Facility. It Makes Grinding Even Easier

SCHOTT manufactures automotive parts and their Czech facility focuses on producing airbag igniters. On our magnetic chuck, they grind the igniters by dozens. ...Read more

Case studies

Magnetic Chucks Becoming Indispensable at thyssenkrupp rote erde

Production at thyssenkrupp rothe erde would never run so smoothly without magnetic chucks. They’re literally indispensable. Read to find out why. ...Read more

At Strojírna Slavíček Industries, Walmag Magnets Make Production Faster, More Precise and Eliminate Reclaims

With more than 15 years of experience with machining on magnetic chucks, Strojírna Slavíček claims that magnets made their production faster and more precise. ...Read more

Case Study: Lifting Magnets NEO a NEO HOT - Siemens

How does Siemens rate NEO lifting magnets? The best proof of their satisfaction is the 160 magnets in their production. Find out why in our article. ...Read more

References

-

Sonicam is working with Walmag since 2011 to ensure a perfect and secured positioning of Glass Industry moulds on our polishing machine thanks to their magnetic holders. With robust and reliable products we ensure our customers a total satisfaction....Read more

-

In 2018 we ordered by Walmag 6 permanent magnetic plates 240mm x 240mm. The magnets had to be adapted to our handling and zero point clamping system.Thanks to the flexibility and the fast delivery time from Walmag, we were able to implement the system on time....Read more

-

De Rooy has been cooperating with Walmag Magnetics since 2013....Read more