Choose a high-quality lifting magnet—you’ll be better off financially (a high-quality magnet will last longer and won’t damage its load) and safety-wise. Although it might be tempting to purchase an inexpensive lifting or clamping magnet, don’t; such a purchase may easily backfire. We’re here to show you how to recognise low-quality magnets and explain why you should avoid them.

Construction, joints, and the lifting handle

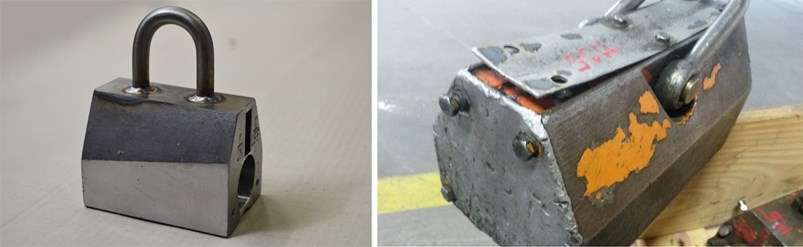

A high-quality lifting magnet should be one compact sturdy piece of metal with welded joints. Contrary to low-quality magnets that often consist of multiple components bolted into one. Such construction requires regular maintenance and always starts to fall apart after you’ve been using the magnet for a while.

Magnets with bolted joints (on the right) fall apart sooner or later. Magnets with welded joints (on the left) last much longer.

The only bolts on a high-quality magnet are the ones attaching the lifting handle to the core of the magnet. We recommend checking whether countersunk bolts are used in the magnet, whether these are level with it and are sturdy enough so as not to get damaged easily.

The lifting handle should be stable in one position—handles of inexpensive magnets often fall from side to side. That can even block the activation switch and represent a safety risk for the operator (look at the handle in the right picture).

Switch levers

Switch levers of high-quality magnets can be operated with just one hand which leaves the operator’s other hand free to perform other tasks, such as operating the lifting crane. Thanks to this, the entire clamping and lifting process is much safer. The switch lever should be made of steel or aluminium, with an ergonomic grip and with ball bearings to switch easily and smoothly. Operating a switch lever of a lifting magnet should be as simple as driving a car with manual transmission.

Switch levers of low-quality magnets typically require more force, have to be operated with both hands and some even shoot back to the OFF position on their own, which is extremely unsafe.

Another typical flaw of low-quality magnets (often those made in China) is residual magnetism. Magnets with residual magnetism can attract loads up to tens of kilograms which often leads to accidents and load damage. Ideally, the magnet should emit absolutely zero magnetic force immediately after it’s switched off.

Certification and tests

When purchasing a lifting magnet, always check that they’re certified and comply with all relevant safety regulations. In Europe, they should be compliant with EN 13155:2020(E) safety standard. The most important parameters are:

- electromagnets should lift and hold twice their maximal load capacity,

- electropermanent magnets should lift and hold 3× their maximal load capacity, with immediate monitoring of the lifting force up to twice of their nominal lifting capacity,

- and permanent neodymium magnets have to be able to lift and hold 3× their maximal load capacity.

If a magnet does not comply with the EN 13155:2020(E) standard, you can never be sure of its actual load capacity. Every producer of lifting magnets should perform load capacity tests regularly. When testing lifting magnets at Walmag, we put a sheet of paper between the magnet and the load, thus decreasing the magnetic force (we create a tiny air capsule that simulates surface irregularities that often occur in reality). As a result, our magnets comply with all relevant safety standards and can in reality lift three times their maximal load capacity. Even through a sheet of paper.

In addition, we recommend choosing a magnet with a European CE certification which sets requirements for properties of magnet components, for technical processes or staff training.

Instruction Manual

This is more about the quality of the producer, not of the magnet itself. You should always receive a thorough instruction manual with your magnet that should be well-structured and easy to understand. It should contain:

- detailed lifting instructions,

- load capacity for different types of load,

- information on how the load capacity can be affected by loads with air capsules, round loads or different types of metals.

In case you need advice on choosing the best lifting magnet, don’t hesitate to contact us.

We’ll consider your unique conditions (in production or in your warehouse) and will always do our best to find the optimal and the safest solution for you.